Product Description

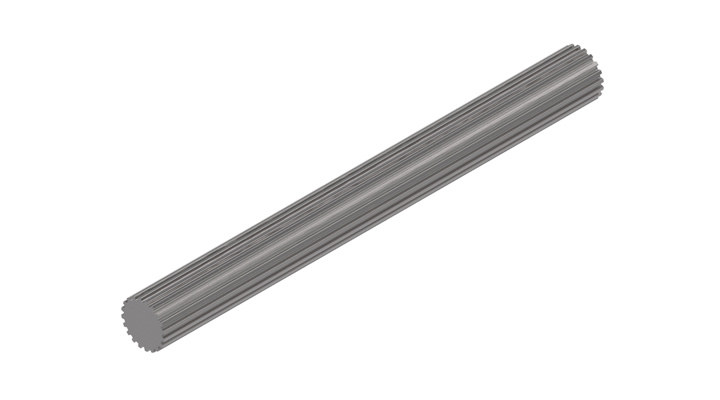

Wide Angle Pto Adaptor Cardan Spline Shaft Yoke Tube Torque Limiter Universal Joint cross Cover Agricultural Machinery Tractor Parts Pto Drive Shaft

Product Description

A PTO shaft (Power Take-Off shaft) is a mechanical component used to transfer power from a tractor or other power source to an attached implement such as a mower, tiller, or baler. The PTO shaft is typically located at the rear of the tractor and is powered by the tractor’s engine through the transmission.

The PTO shaft is designed to provide a rotating power source to the implement, allowing it to perform its intended function. The implement is connected to the PTO shaft using a universal joint, which allows for movement between the tractor and the implement while still maintaining a constant power transfer.

Here is our advantages when compare to similar products from China:

1.Forged yokes make PTO shafts strong enough for usage and working;

2.Internal sizes standard to confirm installation smooth;

3.CE and ISO certificates to guarantee to quality of our goods;

4.Strong and professional package to confirm the good situation when you receive the goods.

Product Specifications

| SHIELD S | SHIELD W |

Packaging & Shipping

Company Profile

HangZhou Hanon Technology Co.,ltd is a modern enterprise specilizing in the development,production,sales and services of Agricultural Parts like PTO shaft and Gearboxes and Hydraulic parts like Cylinder , Valve ,Gearpump and motor etc..

We adhere to the principle of ” High Quality, Customers’Satisfaction”, using advanced technology and equipments to ensure all the technical standards of transmission .We follow the principle of people first , trying our best to set up a pleasant surroundings and platform of performance for each employee. So everyone can be self-consciously active to join Hanon Machinery.

FAQ

1.What’re your main products?

we currently product Agricultural Parts like PTO shaft and Gearboxes and Hydraulic parts like Cylinder , Valve ,Gear pump and motor.You can check the specifications for above product on our website and you can email us to recommend needed product per your specification too.

2.What’s the lead time for a regular order?

Generally speaking, our regular standard product will need 30-45days, a bit longer for customized products. But we are very flexible on the lead time, it will depend on the specific orders.

3.What’s your warranty terms?

One year.

4.Can you send me a price list?

For all of our product, they are customized based on different requirements like length, ratio,voltage,and power etc. The price also varies according to annual quantity. So it’s really difficult for us to provide a price list. If you can share your detailed requirements and annual quantity, we’ll see what offer we can provide.

5.What’s the payment term?

When we quote for you,we will confirm with you the way of transaction,FOB,CIFetc.<br> For mass production goods, you need to pay 30% deposit before producing and70% balance against copy of documents.The most common way is by T/T.

6.How to deliver the goods to us?

Usually we will ship the goods to you by sea.

PTO Drive Shaft Parts

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Agricultural Spare Part, Agricultural Spare Part |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying, Agricultural Machinery,Farm Tractor, Agricultural Products Processing, Farmland Infrastructure, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying, Agricultural Machinery, Farm Tractor |

| Material: | Carbon Steel, 45cr Steel, Carbon Steel |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can spline shafts be customized for specific machinery and equipment?

Yes, spline shafts can be customized to suit specific machinery and equipment requirements. Here’s a detailed explanation:

1. Size and Length:

Spline shafts can be customized in terms of size and length to fit the dimensions of the machinery or equipment. Manufacturers can design spline shafts with the appropriate diameter, overall length, and spline length to ensure a proper fit within the system.

2. Spline Profile:

The spline profile can be customized based on the specific application. Different spline profiles, such as involute, serrated, or helical, can be used to optimize torque transmission, load distribution, and engagement characteristics based on the requirements of the machinery or equipment.

3. Number of Splines:

The number of splines on the shaft can be customized to match the mating component. The number of splines determines the engagement area and affects the torque-carrying capacity of the spline shaft. By adjusting the number of splines, manufacturers can tailor the spline shaft to the specific torque and load requirements of the machinery or equipment.

4. Material Selection:

The choice of material for spline shafts can be customized based on the operating conditions and environmental factors of the machinery or equipment. Different materials, such as alloy steels or stainless steels, can be selected to provide the necessary strength, durability, corrosion resistance, or other specific properties required for the application.

5. Surface Treatment:

The surface of spline shafts can be customized with various treatments to enhance their performance. Surface treatments like heat treatment, coating, or plating can be applied to improve hardness, wear resistance, or corrosion resistance based on the specific requirements of the machinery or equipment.

6. Tolerances and Fit:

Tolerances and fit between the spline shaft and mating components can be customized to achieve the desired clearance or interference fit. This ensures proper engagement, smooth operation, and optimal performance of the machinery or equipment.

7. Special Features:

In certain cases, spline shafts can be customized with additional features to meet specific needs. This may include the incorporation of keyways, threads, or other specialized features required for the machinery or equipment.

Manufacturers and engineers work closely with the machinery or equipment designers to understand the specific requirements and tailor the spline shafts accordingly. By considering factors such as size, spline profile, number of splines, material selection, surface treatment, tolerances, fit, and any special features, customized spline shafts can be developed to ensure optimal performance and compatibility with the machinery or equipment.

It is important to consult with experienced spline shaft manufacturers or engineering professionals to determine the most suitable customization options for a particular machinery or equipment application.

What materials are commonly used in the construction of spline shafts?

Various materials are commonly used in the construction of spline shafts, depending on the specific application requirements. Here’s a list of commonly used materials:

1. Steel:

Steel is one of the most widely used materials for spline shafts. Different grades of steel, such as carbon steel, alloy steel, or stainless steel, can be employed based on factors like strength, hardness, and corrosion resistance. Steel offers excellent mechanical properties, including high strength, durability, and wear resistance, making it suitable for a broad range of applications.

2. Alloy Steel:

Alloy steel is a type of steel that contains additional alloying elements, such as chromium, molybdenum, or nickel. These alloying elements enhance the mechanical properties of the steel, providing improved strength, toughness, and wear resistance. Alloy steel spline shafts are commonly used in applications that require high torque capacity, durability, and resistance to fatigue.

3. Stainless Steel:

Stainless steel is known for its corrosion resistance properties, making it suitable for applications where the spline shaft is exposed to moisture or corrosive environments. Stainless steel spline shafts are commonly used in industries such as food processing, chemical processing, marine, and medical equipment.

4. Aluminum:

Aluminum is a lightweight material with good strength-to-weight ratio. It is often used in applications where weight reduction is a priority, such as automotive and aerospace industries. Aluminum spline shafts can provide advantages such as decreased rotating mass and improved fuel efficiency.

5. Titanium:

Titanium is a strong and lightweight material with excellent corrosion resistance. It is commonly used in high-performance applications where weight reduction, strength, and corrosion resistance are critical factors. Titanium spline shafts find applications in aerospace, motorsports, and high-end industrial equipment.

6. Brass:

Brass is an alloy of copper and zinc, offering good machinability and corrosion resistance. It is often used in applications that require electrical conductivity or a non-magnetic property. Brass spline shafts can be found in industries such as electronics, telecommunications, and instrumentation.

7. Plastics and Composite Materials:

In certain applications where weight reduction, corrosion resistance, or noise reduction is important, plastics or composite materials can be used for spline shafts. Materials such as nylon, acetal, or fiber-reinforced composites can provide specific advantages in terms of weight, low friction, and resistance to chemicals.

It’s important to note that material selection for spline shafts depends on factors such as load requirements, environmental conditions, operating temperatures, and cost considerations. Engineers and designers evaluate these factors to determine the most suitable material for a given application.

Can you explain the common applications of spline shafts in machinery?

Spline shafts have various common applications in machinery where torque transmission, relative movement, and load distribution are essential. Here’s a detailed explanation:

1. Gearboxes and Transmissions:

Spline shafts are commonly used in gearboxes and transmissions where they facilitate the transmission of torque from the input shaft to the output shaft. The splines on the shaft engage with corresponding splines on the gears, allowing for precise torque transfer and accommodating relative movement between the gears.

2. Power Take-Off (PTO) Units:

In agricultural and industrial machinery, spline shafts are employed in power take-off (PTO) units. PTO units allow the transfer of power from the engine to auxiliary equipment, such as pumps, generators, or farm implements. Spline shafts enable the torque transfer and accommodate the relative movement required for PTO operation.

3. Steering Systems:

Spline shafts play a crucial role in steering systems, especially in vehicles. They are used in steering columns to transmit torque from the steering wheel to the steering rack or gearbox. The splines on the shaft ensure precise torque transfer while allowing for the axial movement required for steering wheel adjustment.

4. Machine Tools:

Spline shafts find applications in machine tools such as milling machines, lathes, and grinding machines. They are used to transmit torque and enable the relative movement required for tool positioning, feed control, and spindle rotation. Spline shafts ensure accurate and controlled movement of the machine tool components.

5. Industrial Pumps and Compressors:

Spline shafts are utilized in various types of pumps and compressors, including centrifugal pumps, gear pumps, and reciprocating compressors. They transmit torque from the driver (such as an electric motor or an engine) to the impeller or rotor, enabling fluid or gas transfer. Spline shafts accommodate the axial or radial movement caused by thermal expansion or misalignment.

6. Printing and Packaging Machinery:

Spline shafts are integral components in printing and packaging machinery. They are used in processes such as web handling, where precise torque transmission and relative movement are required for tasks like tension control, registration, and material feeding. Spline shafts ensure accurate and synchronized movement of the printing and packaging elements.

7. Aerospace and Defense Systems:

In the aerospace and defense industries, spline shafts are utilized in various applications, including aircraft landing gear systems, missile guidance systems, and helicopter rotor systems. They enable torque transmission, accommodate relative movement, and ensure precise control in critical aerospace and defense mechanisms.

8. Construction and Earthmoving Equipment:

Spline shafts are employed in construction and earthmoving equipment, such as excavators, bulldozers, and loaders. They are used in hydraulic systems to transmit torque from the hydraulic motor to the driven components, such as the digger arm or the bucket. Spline shafts enable efficient power transfer and allow for the articulation and movement of the equipment.

These are just a few examples of the common applications of spline shafts in machinery. Their versatility, torque transmission capabilities, and ability to accommodate relative movement make them essential components in various industries where precise power transfer and flexibility are required.

editor by CX 2024-03-26

China wholesaler Professional Manufacturer Agricultural Machinery Use Power Cross Joint Transmission Shaft Pto Shaft and Drive Shaft with Good quality

Product Description

Agricultural Machinery Use Power Cross Joint Transmission Shaft Pto Shaft and Drive Shaft

HangZhou CZPT International Trading Co.,Ltd is a modern enterprise specilizing in the development, production, sales and services of PTO shaft. We adhere to the principle of “Precise Driveline, Advocate Green”, using advanced technology and equipments to ensure all the technical standards of precise driveline. So that the transmission efficiency can be maxmized and every drop of resource of customers’ can be saved. Meanwhile, we have a customer-centric service system, providing a full range of pre-sale, sale and after-sale service. Customer satisfaction is our forever pursuit.

We follow the principle of people first, trying our best to set up a pleasant surroundings and platform of performance for each employee, so everyone can be self-consciously active to join in “Precise Driveline, Adocate Green” to embody the self-worth, enterprise value and social value.

Newnuro’s goal is: reducing customer’s purchase budget, support customers to earn more market.

Newnuro always finds solution for customers.Customer satisfaction is our ultimate goal and forever pursuit.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Assembled |

| Samples: |

US$ 8/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Applications of Spline Couplings

A spline coupling is a highly effective means of connecting two or more components. These types of couplings are very efficient, as they combine linear motion with rotation, and their efficiency makes them a desirable choice in numerous applications. Read on to learn more about the main characteristics and applications of spline couplings. You will also be able to determine the predicted operation and wear. You can easily design your own couplings by following the steps outlined below.

Optimal design

The spline coupling plays an important role in transmitting torque. It consists of a hub and a shaft with splines that are in surface contact without relative motion. Because they are connected, their angular velocity is the same. The splines can be designed with any profile that minimizes friction. Because they are in contact with each other, the load is not evenly distributed, concentrating on a small area, which can deform the hub surface.

Optimal spline coupling design takes into account several factors, including weight, material characteristics, and performance requirements. In the aeronautics industry, weight is an important design factor. S.A.E. and ANSI tables do not account for weight when calculating the performance requirements of spline couplings. Another critical factor is space. Spline couplings may need to fit in tight spaces, or they may be subject to other configuration constraints.

Optimal design of spline couplers may be characterized by an odd number of teeth. However, this is not always the case. If the external spline’s outer diameter exceeds a certain threshold, the optimal spline coupling model may not be an optimal choice for this application. To optimize a spline coupling for a specific application, the user may need to consider the sizing method that is most appropriate for their application.

Once a design is generated, the next step is to test the resulting spline coupling. The system must check for any design constraints and validate that it can be produced using modern manufacturing techniques. The resulting spline coupling model is then exported to an optimisation tool for further analysis. The method enables a designer to easily manipulate the design of a spline coupling and reduce its weight.

The spline coupling model 20 includes the major structural features of a spline coupling. A product model software program 10 stores default values for each of the spline coupling’s specifications. The resulting spline model is then calculated in accordance with the algorithm used in the present invention. The software allows the designer to enter the spline coupling’s radii, thickness, and orientation.

Characteristics

An important aspect of aero-engine splines is the load distribution among the teeth. The researchers have performed experimental tests and have analyzed the effect of lubrication conditions on the coupling behavior. Then, they devised a theoretical model using a Ruiz parameter to simulate the actual working conditions of spline couplings. This model explains the wear damage caused by the spline couplings by considering the influence of friction, misalignment, and other conditions that are relevant to the splines’ performance.

In order to design a spline coupling, the user first inputs the design criteria for sizing load carrying sections, including the external spline 40 of the spline coupling model 30. Then, the user specifies torque margin performance requirement specifications, such as the yield limit, plastic buckling, and creep buckling. The software program then automatically calculates the size and configuration of the load carrying sections and the shaft. These specifications are then entered into the model software program 10 as specification values.

Various spline coupling configuration specifications are input on the GUI screen 80. The software program 10 then generates a spline coupling model by storing default values for the various specifications. The user then can manipulate the spline coupling model by modifying its various specifications. The final result will be a computer-aided design that enables designers to optimize spline couplings based on their performance and design specifications.

The spline coupling model software program continually evaluates the validity of spline coupling models for a particular application. For example, if a user enters a data value signal corresponding to a parameter signal, the software compares the value of the signal entered to the corresponding value in the knowledge base. If the values are outside the specifications, a warning message is displayed. Once this comparison is completed, the spline coupling model software program outputs a report with the results.

Various spline coupling design factors include weight, material properties, and performance requirements. Weight is one of the most important design factors, particularly in the aeronautics field. ANSI and S.A.E. tables do not consider these factors when calculating the load characteristics of spline couplings. Other design requirements may also restrict the configuration of a spline coupling.

Applications

Spline couplings are a type of mechanical joint that connects two rotating shafts. Its two parts engage teeth that transfer load. Although splines are commonly over-dimensioned, they are still prone to fatigue and static behavior. These properties also make them prone to wear and tear. Therefore, proper design and selection are vital to minimize wear and tear on splines. There are many applications of spline couplings.

A key design is based on the size of the shaft being joined. This allows for the proper spacing of the keys. A novel method of hobbing allows for the formation of tapered bases without interference, and the root of the keys is concentric with the axis. These features enable for high production rates. Various applications of spline couplings can be found in various industries. To learn more, read on.

FE based methodology can predict the wear rate of spline couplings by including the evolution of the coefficient of friction. This method can predict fretting wear from simple round-on-flat geometry, and has been calibrated with experimental data. The predicted wear rate is reasonable compared to the experimental data. Friction evolution in spline couplings depends on the spline geometry. It is also crucial to consider the lubrication condition of the splines.

Using a spline coupling reduces backlash and ensures proper alignment of mated components. The shaft’s splined tooth form transfers rotation from the splined shaft to the internal splined member, which may be a gear or other rotary device. A spline coupling’s root strength and torque requirements determine the type of spline coupling that should be used.

The spline root is usually flat and has a crown on one side. The crowned spline has a symmetrical crown at the centerline of the face-width of the spline. As the spline length decreases toward the ends, the teeth are becoming thinner. The tooth diameter is measured in pitch. This means that the male spline has a flat root and a crowned spline.

Predictability

Spindle couplings are used in rotating machinery to connect two shafts. They are composed of two parts with teeth that engage each other and transfer load. Spline couplings are commonly over-dimensioned and are prone to static and fatigue behavior. Wear phenomena are also a common problem with splines. To address these issues, it is essential to understand the behavior and predictability of these couplings.

Dynamic behavior of spline-rotor couplings is often unclear, particularly if the system is not integrated with the rotor. For example, when a misalignment is not present, the main response frequency is one X-rotating speed. As the misalignment increases, the system starts to vibrate in complex ways. Furthermore, as the shaft orbits depart from the origin, the magnitudes of all the frequencies increase. Thus, research results are useful in determining proper design and troubleshooting of rotor systems.

The model of misaligned spline couplings can be obtained by analyzing the stress-compression relationships between two spline pairs. The meshing force model of splines is a function of the system mass, transmitting torque, and dynamic vibration displacement. This model holds when the dynamic vibration displacement is small. Besides, the CZPT stepping integration method is stable and has high efficiency.

The slip distributions are a function of the state of lubrication, coefficient of friction, and loading cycles. The predicted wear depths are well within the range of measured values. These predictions are based on the slip distributions. The methodology predicts increased wear under lightly lubricated conditions, but not under added lubrication. The lubrication condition and coefficient of friction are the key factors determining the wear behavior of splines.

editor by CX 2024-03-25

China High-precision welding Excellent quality Spline coupling Airfoil cross shaft equipment Universal joint fork drive shaft carrier bearing

Guarantee: 1 several years

Relevant Industries: Resorts, Garment Stores, Developing Content Retailers, Producing Plant, Machinery Mend Shops, Meals & Beverage Manufacturing unit, Farms, Restaurant, House Use, Retail, Foods Store, Printing Stores, Construction works , Power & Mining, Foodstuff & Beverage Retailers, Other, Marketing Business

Structure: Gear

Flexible or Rigid: Rigid

Standard or Nonstandard: Common

Content: Stainless steel

Item identify: Conjoined travel shaft

Coating: 118mm

Rated torque: 25 for CZPT xc90 xc60 2016- Push Shaft Entrance Left Xihu (West Lake) Dis. Port, ZheJiang Port, HangZhou Port, HangZhou Port

VR Higher-precision welding Exceptional high quality Spline coupling Airfoil cross shaft tools Universal joint forkThe mixed generate shaft cross shaft consists of universal joints, spline core elements, with help, and spline pairs are retractable. They are utilized in engineering machinery processing plants, auto manufacturers, OEMs, constructing resources merchants, makers, machinery restore shops, and so forth. Item requirements

| Product quantity | Maximum torque (N.m) | Rotation diameter (mm) | Rated torque (N.m) | Universal joint dimension(mm) | Diameter of shaft tube (mm) |

| BJ130 | 2500 | Ø110 | 2700 | Φ32×93 | Ø63.5 |

| NJ130 | 3200 | Ø118 | 2500 | Φ35× Custom-made high top quality CNC machined sprockets ninety eight | Ø76 |

| 35106 | 5000 | Ø130 | 2800 | Φ35×107 | Ø89 |

| EQ140 | 6500 | Ø142 | 4100 | Φ39×118 | Ø89 |

The Different Types of Splines in a Splined Shaft

A splined shaft is a machine component with internal and external splines. The splines are formed in four different ways: Involute, Parallel, Serrated, and Ball. You can learn more about each type of spline in this article. When choosing a splined shaft, be sure to choose the right one for your application. Read on to learn about the different types of splines and how they affect the shaft’s performance.

Involute splines

Involute splines in a splined shaft are used to secure and extend mechanical assemblies. They are smooth, inwardly curving grooves that resist separation during operation. A shaft with involute splines is often longer than the shaft itself. This feature allows for more axial movement. This is beneficial for many applications, especially in a gearbox.

The involute spline is a shaped spline, similar to a parallel spline. It is angled and consists of teeth that create a spiral pattern that enables linear and rotatory motion. It is distinguished from other splines by the serrations on its flanks. It also has a flat top. It is a good option for couplers and other applications where angular movement is necessary.

Involute splines are also called involute teeth because of their shape. They are flat on the top and curved on the sides. These teeth can be either internal or external. As a result, involute splines provide greater surface contact, which helps reduce stress and fatigue. Regardless of the shape, involute splines are generally easy to machine and fit.

Involute splines are a type of splines that are used in splined shafts. These splines have different names, depending on their diameters. An example set of designations is for a 32-tooth male spline, a 2,500-tooth module, and a 30 degree pressure angle. An example of a female spline, a fillet root spline, is used to describe the diameter of the splined shaft.

The effective tooth thickness of splines is dependent on the number of keyways and the type of spline. Involute splines in splined shafts should be designed to engage 25 to 50 percent of the spline teeth during the coupling. Involute splines should be able to withstand the load without cracking.

Parallel splines

Parallel splines are formed on a splined shaft by putting one or more teeth into another. The male spline is positioned at the center of the female spline. The teeth of the male spline are also parallel to the shaft axis, but a common misalignment causes the splines to roll and tilt. This is common in many industrial applications, and there are a number of ways to improve the performance of splines.

Typically, parallel splines are used to reduce friction in a rotating part. The splines on a splined shaft are narrower on the end face than the interior, which makes them more prone to wear. This type of spline is used in a variety of industries, such as machinery, and it also allows for greater efficiency when transmitting torque.

Involute splines on a splined shaft are the most common. They have equally spaced teeth, and are therefore less likely to crack due to fatigue. They also tend to be easy to cut and fit. However, they are not the best type of spline. It is important to understand the difference between parallel and involute splines before deciding on which spline to use.

The difference between splined and involute splines is the size of the grooves. Involute splines are generally larger than parallel splines. These types of splines provide more torque to the gear teeth and reduce stress during operation. They are also more durable and have a longer life span. And because they are used on farm machinery, they are essential in this type of application.

Serrated splines

A Serrated Splined Shaft has several advantages. This type of shaft is highly adjustable. Its large number of teeth allows large torques, and its shorter tooth width allows for greater adjustment. These features make this type of shaft an ideal choice for applications where accuracy is critical. Listed below are some of the benefits of this type of shaft. These benefits are just a few of the advantages. Learn more about this type of shaft.

The process of hobbing is inexpensive and highly accurate. It is useful for external spline shafts, but is not suitable for internal splines. This type of process forms synchronized shapes on the shaft, reducing the manufacturing cycle and stabilizing the relative phase between spline and thread. It uses a grinding wheel to shape the shaft. CZPT Manufacturing has a large inventory of Serrated Splined Shafts.

The teeth of a Serrated Splined Shaft are designed to engage with the hub over the entire circumference of the shaft. The teeth of the shaft are spaced uniformly around the spline, creating a multiple-tooth point of contact over the entire length of the shaft. The results of these analyses are usually satisfactory. But there are some limitations. To begin with, the splines of the Serrated Splined Shaft should be chosen carefully. If the application requires large-scale analysis, it may be necessary to modify the design.

The splines of the Serrated Splined Shaft are also used for other purposes. They can be used to transmit torque to another device. They also act as an anti-rotational device and function as a linear guide. Both the design and the type of splines determine the function of the Splined Shaft. In the automobile industry, they are used in vehicles, aerospace, earth-moving machinery, and many other industries.

Ball splines

The invention relates to a ball-spinned shaft. The shaft comprises a plurality of balls that are arranged in a series and are operatively coupled to a load path section. The balls are capable of rolling endlessly along the path. This invention also relates to a ball bearing. Here, a ball bearing is one of the many types of gears. The following discussion describes the features of a ball bearing.

A ball-splined shaft assembly comprises a shaft with at least one ball-spline groove and a plurality of circumferential step grooves. The shaft is held in a first holding means that extends longitudinally and is rotatably held by a second holding means. Both the shaft and the first holding means are driven relative to one another by a first driving means. It is possible to manufacture a ball-splined shaft in a variety of ways.

A ball-splined shaft features a nut with recirculating balls. The ball-splined nut rides in these grooves to provide linear motion while preventing rotation. A splined shaft with a nut that has recirculating balls can also provide rotary motion. A ball splined shaft also has higher load capacities than a ball bushing. For these reasons, ball splines are an excellent choice for many applications.

In this invention, a pair of ball-spinned shafts are housed in a box under a carrier device 40. Each of the two shafts extends along a longitudinal line of arm 50. One end of each shaft is supported rotatably by a slide block 56. The slide block also has a support arm 58 that supports the center arm 50 in a cantilever fashion.

Sector no-go gage

A no-go gauge is a tool that checks the splined shaft for oversize. It is an effective way to determine the oversize condition of a splined shaft without removing the shaft. It measures external splines and serrations. The no-go gage is available in sizes ranging from 19mm to 130mm with a 25mm profile length.

The sector no-go gage has two groups of diametrally opposed teeth. The space between them is manufactured to a maximum space width and the tooth thickness must be within a predetermined tolerance. This gage would be out of tolerance if the splines were measured with a pin. The dimensions of this splined shaft can be found in the respective ANSI or DIN standards.

The go-no-go gage is useful for final inspection of thread pitch diameter. It is also useful for splined shafts and threaded nuts. The thread of a screw must match the contour of the go-no-go gage head to avoid a no-go condition. There is no substitute for a quality machine. It is an essential tool for any splined shaft and fastener manufacturer.

The NO-GO gage can detect changes in tooth thickness. It can be calibrated under ISO17025 standards and has many advantages over a non-go gage. It also gives a visual reference of the thickness of a splined shaft. When the teeth match, the shaft is considered ready for installation. It is a critical process. In some cases, it is impossible to determine the precise length of the shaft spline.

The 45-degree pressure angle is most commonly used for axles and torque-delivering members. This pressure angle is the most economical in terms of tool life, but the splines will not roll neatly like a 30 degree angle. The 45-degree spline is more likely to fall off larger than the other two. Oftentimes, it will also have a crowned look. The 37.5 degree pressure angle is a compromise between the other two pressure angles. It is often used when the splined shaft material is harder than usual.

editor by czh 2023-02-18

China Agricultural PTO Shaft Yoke Tractor Clutch Spline Joint Cardan Couplings Cross Drive Universal Propeller Metal u power take off front drive shaft

Condition: New

Warranty: 1.5 years

Applicable Industries: Producing Plant, Equipment Fix Stores, Farms

Showroom Area: None

Video clip outgoing-inspection: Supplied

Equipment Check Report: Supplied

Marketing Type: Common Merchandise

Type: Shafts

Neighborhood Services Place: Italy

certification: CE

Materials: Metal

Processing of yoke: Forging

Layout: Customized

Certification: CE Certification

Following Warranty Provider: On the internet assistance

Nearby Service Location: None

Packaging Information: carton/iron crate

Port: HangZhou or ZheJiang

Items DescriptionAgricultural PTO Shaft Yoke Tractor Clutch Spline Joint Cardan Couplings Cross Push Common Propeller Metallic u electrical power consider offThe power take-off (PTO) is a refined system, enabling implements to attract energy from the engine and transmit it to yet another application. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.The power consider-off shaft (PTO shaft) is a essential ingredient, developed and manufactured for constant heavy-duty use. A excellent PTO shaft need to be robust sufficient to bear the torsion and shear pressure and lessen vibration. Setforge, the forging subsidiary of Ever-Energy Group, manufactures cold extruded PTO shafts for all varieties of agriculture vehicles.Our PTO shafts supply wonderful dependability and longevity during every day use.EP Team has been internationally acknowledged as a trustworthy worldwide supplier. Our state-of-the-art producing approach andexperienced engineers guarantee the leading-top quality of all Farinia factors. Relevant ProductsCompany InformationEVER-Electricity Group Specialist IN Creating ALL Kinds OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL Gear Pace REDUCERS, ARALLEL SHAFT HELICAL Gear REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM Gear REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, Car GEARBOXES, PTO Push SHAFTS, Specific REDUCER & Relevant Equipment Components AND OTHER Connected Merchandise, SPROCKETS, HYDRAULIC Technique, VACUUM PUMPS, FLUID COUPLING, Gear RACKS, CHAINS, 250KW 350Hp 7Bar 8Bar 10Bar 12Bar Stationary Mounted Speed Oil Totally free Air Compressor TIMING PULLEYS, UDL Pace VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, Gear PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS Lower BACKLASH WORM REDUCERS AND SO ON. Furthermore, WE CAN Make Customized VARIATORS, GEARED MOTORS, Electrical MOTORS AND OTHER HYDRAULIC Goods According TO CUSTOMERS’ DRAWINGS. Certifications FAQQ: Are you trading business or company ?A: Our team consists in 3 factories and 2 abroad product sales companies.Q: Do you supply samples ? is it free of charge or further ?A: Yes, we could provide the sample for cost-free demand but do not spend the expense of freight.Q: How lengthy is your shipping time ? What is your phrases of payment ?A: Usually it is forty-45 times. The time may possibly vary relying on the merchandise and the amount of customization. For normal goods, the payment is: 30% T/T in advance ,balance prior to shippment.Q: What is the actual MOQ or price tag for your solution ?A: As an OEM business, we can provide and adapt our merchandise to a wide range of needs.Therefore, MOQ and cost may tremendously vary with measurement, content and further technical specs For instance, costly merchandise or common goods will normally have a reduce MOQ. Please contact us with all related particulars to get the most correct quotation.If you have one more question, make sure you truly feel free of charge to make contact with us.Solution packaging Why Pick UsAlso I would like to get this chance to give a quick introduction of our Ever-Energy organization:Our company is a popular manufacturer of agriculture gearbox,worm reduce gearbox, PTO shafts, Sprockets ,rollar chains, bevel equipment, Casting Ductile Iron Variator Rv Reducer Gearbox Worm Gear Speed Reducer pulleys and racks in china.We have exported numerous products to our buyers all in excess of the globe, we have lengthy-time encounter and strong technology help. Some of our buyer :Italy: GB GEABOX, SATI, CHIARAVALLI, AMA, BreviniGermany: SILOKING ,GKN ,KTSFrance: Itfran, Sedies, KuhnBrazil: AEMCO ,STUUSA: John Deere , BLOUNT, Weasler, Agco, Omni Gear, WOODSCanada: JAY-LOR , CANIMEX ,RingBall……-> Our Business with over twelve year’s history and one thousand employees and twenty income.-> With above 100 Million USD income in 2017-> With progress equipment equipments-> With large work capability and substantial top quality manage, ISO certified…….you also can check our site to know for more particulars, if you need to have our items catalogue, CAM Sprocket Y16ZR SNIPER155 EXCITER155 38T B3M-E2280-00 Motorcycles Modified For CZPT TIMING Gear CAM Sprocket make sure you contact with us.Get in touch with Us

| FOR A lot more Element, You should Speak to US. |

Types of Splines

There are four types of splines: Involute, Parallel key, helical, and ball. Learn about their characteristics. And, if you’re not sure what they are, you can always request a quotation. These splines are commonly used for building special machinery, repair jobs, and other applications. The CZPT Manufacturing Company manufactures these shafts. It is a specialty manufacturer and we welcome your business.

Involute splines

The involute spline provides a more rigid and durable structure, and is available in a variety of diameters and spline counts. Generally, steel, carbon steel, or titanium are used as raw materials. Other materials, such as carbon fiber, may be suitable. However, titanium can be difficult to produce, so some manufacturers make splines using other constituents.

When splines are used in shafts, they prevent parts from separating during operation. These features make them an ideal choice for securing mechanical assemblies. Splines with inward-curving grooves do not have sharp corners and are therefore less likely to break or separate while they are in operation. These properties help them to withstand high-speed operations, such as braking, accelerating, and reversing.

A male spline is fitted with an externally-oriented face, and a female spline is inserted through the center. The teeth of the male spline typically have chamfered tips to provide clearance with the transition area. The radii and width of the teeth of a male spline are typically larger than those of a female spline. These specifications are specified in ANSI or DIN design manuals.

The effective tooth thickness of a spline depends on the involute profile error and the lead error. Also, the spacing of the spline teeth and keyways can affect the effective tooth thickness. Involute splines in a splined shaft are designed so that at least 25 percent of the spline teeth engage during coupling, which results in a uniform distribution of load and wear on the spline.

Parallel key splines

A parallel splined shaft has a helix of equal-sized grooves around its circumference. These grooves are generally parallel or involute. Splines minimize stress concentrations in stationary joints and allow linear and rotary motion. Splines may be cut or cold-rolled. Cold-rolled splines have more strength than cut spines and are often used in applications that require high strength, accuracy, and a smooth surface.

A parallel key splined shaft features grooves and keys that are parallel to the axis of the shaft. This design is best suited for applications where load bearing is a primary concern and a smooth motion is needed. A parallel key splined shaft can be made from alloy steels, which are iron-based alloys that may also contain chromium, nickel, molybdenum, copper, or other alloying materials.

A splined shaft can be used to transmit torque and provide anti-rotation when operating as a linear guide. These shafts have square profiles that match up with grooves in a mating piece and transmit torque and rotation. They can also be easily changed in length, and are commonly used in aerospace. Its reliability and fatigue life make it an excellent choice for many applications.

The main difference between a parallel key splined shaft and a keyed shaft is that the former offers more flexibility. They lack slots, which reduce torque-transmitting capacity. Splines offer equal load distribution along the gear teeth, which translates into a longer fatigue life for the shaft. In agricultural applications, shaft life is essential. Agricultural equipment, for example, requires the ability to function at high speeds for extended periods of time.

Involute helical splines

Involute splines are a common design for splined shafts. They are the most commonly used type of splined shaft and feature equal spacing among their teeth. The teeth of this design are also shorter than those of the parallel spline shaft, reducing stress concentration. These splines can be used to transmit power to floating or permanently fixed gears, and reduce stress concentrations in the stationary joint. Involute splines are the most common type of splined shaft, and are widely used for a variety of applications in automotive, machine tools, and more.

Involute helical spline shafts are ideal for applications involving axial motion and rotation. They allow for face coupling engagement and disengagement. This design also allows for a larger diameter than a parallel spline shaft. The result is a highly efficient gearbox. Besides being durable, splines can also be used for other applications involving torque and energy transfer.

A new statistical model can be used to determine the number of teeth that engage for a given load. These splines are characterized by a tight fit at the major diameters, thereby transferring concentricity from the shaft to the female spline. A male spline has chamfered tips for clearance with the transition area. ANSI and DIN design manuals specify the different classes of fit.

The design of involute helical splines is similar to that of gears, and their ridges or teeth are matched with the corresponding grooves in a mating piece. It enables torque and rotation to be transferred to a mate piece while maintaining alignment of the two components. Different types of splines are used in different applications. Different splines can have different levels of tooth height.

Involute ball splines

When splines are used, they allow the shaft and hub to engage evenly over the shaft’s entire circumference. Because the teeth are evenly spaced, the load that they can transfer is uniform and their position is always the same regardless of shaft length. Whether the shaft is used to transmit torque or to transmit power, splines are a great choice. They provide maximum strength and allow for linear or rotary motion.

There are three basic types of splines: helical, crown, and ball. Crown splines feature equally spaced grooves. Crown splines feature involute sides and parallel sides. Helical splines use involute teeth and are often used in small diameter shafts. Ball splines contain a ball bearing inside the splined shaft to facilitate rotary motion and minimize stress concentration in stationary joints.

The two types of splines are classified under the ANSI classes of fit. Fillet root splines have teeth that mesh along the longitudinal axis of rotation. Flat root splines have similar teeth, but are intended to optimize strength for short-term use. Both types of splines are important for ensuring the shaft aligns properly and is not misaligned.

The friction coefficient of the hub is a complex process. When the hub is off-center, the center moves in predictable but irregular motion. Moreover, when the shaft is centered, the center may oscillate between being centered and being off-center. To compensate for this, the torque must be adequate to keep the shaft in its axis during all rotation angles. While straight-sided splines provide similar centering, they have lower misalignment load factors.

Keyed shafts

Essentially, splined shafts have teeth or ridges that fit together to transfer torque. Because splines are not as tall as involute gears, they offer uniform torque transfer. Additionally, they provide the opportunity for torque and rotational changes and improve wear resistance. In addition to their durability, splined shafts are popular in the aerospace industry and provide increased reliability and fatigue life.

Keyed shafts are available in different materials, lengths, and diameters. When used in high-power drive applications, they offer higher torque and rotational speeds. The higher torque they produce helps them deliver power to the gearbox. However, they are not as durable as splined shafts, which is why the latter is usually preferred in these applications. And while they’re more expensive, they’re equally effective when it comes to torque delivery.

Parallel keyed shafts have separate profiles and ridges and are used in applications requiring accuracy and precision. Keyed shafts with rolled splines are 35% stronger than cut splines and are used where precision is essential. These splines also have a smooth finish, which can make them a good choice for precision applications. They also work well with gears and other mechanical systems that require accurate torque transfer.

Carbon steel is another material used for splined shafts. Carbon steel is known for its malleability, and its shallow carbon content helps create reliable motion. However, if you’re looking for something more durable, consider ferrous steel. This type contains metals such as nickel, chromium, and molybdenum. And it’s important to remember that carbon steel is not the only material to consider.

editor by czh 2023-02-15

China Fine workmanship flexible universal joint spline shaft coupling farm cardan shaft durable Airfoil cross shaft custom drive shaft

Condition: New

Warranty: 1 Year

Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Advertising Company

Weight (KG): 13.2

Showroom Location: None

Video outgoing-inspection: Provided

Machinery Test Report: Provided

Marketing Type: New Product 2571

Warranty of core components: 1 Year

Core Components: Bearing, Spline pair

Structure: Flexible

Material: 40Cr/45#

Coatings: paint

Torque Capacity: 2500

Model Number: BJ130

Product name: Drive shaft with support

Coating: 110mm

Rated torque: 2700

Application: Various vehicles

Features: Coated nylon enhances wear resistance, strength, corrosion protection

Universal joint size: 32*93

Diameter of shaft tube: 63.5mm

Certification: IATF16949:2016 Quality System

MOQ: 2 Piece

Quality: 7~13.2kg

Packaging Details: Wooden box or other

Port: HangZhou Port, Xihu (West Lake) Dis. Port, ZheJiang Port, HangZhou Port, HangZhou Port

VR Fine workmanship flexible universal joint spline shaft coupling farm cardan shaft durable Airfoil cross shaftWith supporting transmission shaft belt support, the spline pair cannot be extended and contracted. The core component is a cross shaft universal joint and a spline pair, which are used in construction machinery processing plants, automobile manufacturers, OEMs, building materials shops, manufacturers, machinery repair shops, etc. Product specifications

| Product number | Maximum torque (N.m) | Rotation diameter (mm) | Rated torque (N.m) | Universal joint size(mm) | Diameter of shaft tube (mm) |

| BJ130 | 2500 | Ø110 | 2700 | Φ32×93 | Ø63.5 |

| NJ130 | 3200 | Ø118 | 2500 | Φ35×98 | Ø76 |

| EQ140 | 6500 | Ø142 | 4100 | Φ39×118 | Ø89 |

| EQ153 | 9000 | Ø165 | 6000 | Φ47×140 | Ø89 |

| 0125 | 16500 | Ø156 | 10000 | Φ52×133 | Ø100 |

| 0082 | 21000 | Ø168 | 15000 | Φ57×144 | Ø110 |

| 395 | 27000 | Ø178 | 17000 | Φ57×152 | Ø120 |

| 656 | 44000 | Ø198 | 25000 | Φ68×165 | Ø140 |

| Y165E1 | 52500 | Ø210 | 30000 | Φ68×193 | Ø150 |

Applications of Spline Couplings

A spline coupling is a highly effective means of connecting two or more components. These types of couplings are very efficient, as they combine linear motion with rotation, and their efficiency makes them a desirable choice in numerous applications. Read on to learn more about the main characteristics and applications of spline couplings. You will also be able to determine the predicted operation and wear. You can easily design your own couplings by following the steps outlined below.

Optimal design

The spline coupling plays an important role in transmitting torque. It consists of a hub and a shaft with splines that are in surface contact without relative motion. Because they are connected, their angular velocity is the same. The splines can be designed with any profile that minimizes friction. Because they are in contact with each other, the load is not evenly distributed, concentrating on a small area, which can deform the hub surface.

Optimal spline coupling design takes into account several factors, including weight, material characteristics, and performance requirements. In the aeronautics industry, weight is an important design factor. S.A.E. and ANSI tables do not account for weight when calculating the performance requirements of spline couplings. Another critical factor is space. Spline couplings may need to fit in tight spaces, or they may be subject to other configuration constraints.

Optimal design of spline couplers may be characterized by an odd number of teeth. However, this is not always the case. If the external spline’s outer diameter exceeds a certain threshold, the optimal spline coupling model may not be an optimal choice for this application. To optimize a spline coupling for a specific application, the user may need to consider the sizing method that is most appropriate for their application.

Once a design is generated, the next step is to test the resulting spline coupling. The system must check for any design constraints and validate that it can be produced using modern manufacturing techniques. The resulting spline coupling model is then exported to an optimisation tool for further analysis. The method enables a designer to easily manipulate the design of a spline coupling and reduce its weight.

The spline coupling model 20 includes the major structural features of a spline coupling. A product model software program 10 stores default values for each of the spline coupling’s specifications. The resulting spline model is then calculated in accordance with the algorithm used in the present invention. The software allows the designer to enter the spline coupling’s radii, thickness, and orientation.

Characteristics

An important aspect of aero-engine splines is the load distribution among the teeth. The researchers have performed experimental tests and have analyzed the effect of lubrication conditions on the coupling behavior. Then, they devised a theoretical model using a Ruiz parameter to simulate the actual working conditions of spline couplings. This model explains the wear damage caused by the spline couplings by considering the influence of friction, misalignment, and other conditions that are relevant to the splines’ performance.

In order to design a spline coupling, the user first inputs the design criteria for sizing load carrying sections, including the external spline 40 of the spline coupling model 30. Then, the user specifies torque margin performance requirement specifications, such as the yield limit, plastic buckling, and creep buckling. The software program then automatically calculates the size and configuration of the load carrying sections and the shaft. These specifications are then entered into the model software program 10 as specification values.

Various spline coupling configuration specifications are input on the GUI screen 80. The software program 10 then generates a spline coupling model by storing default values for the various specifications. The user then can manipulate the spline coupling model by modifying its various specifications. The final result will be a computer-aided design that enables designers to optimize spline couplings based on their performance and design specifications.

The spline coupling model software program continually evaluates the validity of spline coupling models for a particular application. For example, if a user enters a data value signal corresponding to a parameter signal, the software compares the value of the signal entered to the corresponding value in the knowledge base. If the values are outside the specifications, a warning message is displayed. Once this comparison is completed, the spline coupling model software program outputs a report with the results.

Various spline coupling design factors include weight, material properties, and performance requirements. Weight is one of the most important design factors, particularly in the aeronautics field. ANSI and S.A.E. tables do not consider these factors when calculating the load characteristics of spline couplings. Other design requirements may also restrict the configuration of a spline coupling.

Applications

Spline couplings are a type of mechanical joint that connects two rotating shafts. Its two parts engage teeth that transfer load. Although splines are commonly over-dimensioned, they are still prone to fatigue and static behavior. These properties also make them prone to wear and tear. Therefore, proper design and selection are vital to minimize wear and tear on splines. There are many applications of spline couplings.

A key design is based on the size of the shaft being joined. This allows for the proper spacing of the keys. A novel method of hobbing allows for the formation of tapered bases without interference, and the root of the keys is concentric with the axis. These features enable for high production rates. Various applications of spline couplings can be found in various industries. To learn more, read on.

FE based methodology can predict the wear rate of spline couplings by including the evolution of the coefficient of friction. This method can predict fretting wear from simple round-on-flat geometry, and has been calibrated with experimental data. The predicted wear rate is reasonable compared to the experimental data. Friction evolution in spline couplings depends on the spline geometry. It is also crucial to consider the lubrication condition of the splines.

Using a spline coupling reduces backlash and ensures proper alignment of mated components. The shaft’s splined tooth form transfers rotation from the splined shaft to the internal splined member, which may be a gear or other rotary device. A spline coupling’s root strength and torque requirements determine the type of spline coupling that should be used.

The spline root is usually flat and has a crown on one side. The crowned spline has a symmetrical crown at the centerline of the face-width of the spline. As the spline length decreases toward the ends, the teeth are becoming thinner. The tooth diameter is measured in pitch. This means that the male spline has a flat root and a crowned spline.

Predictability

Spindle couplings are used in rotating machinery to connect two shafts. They are composed of two parts with teeth that engage each other and transfer load. Spline couplings are commonly over-dimensioned and are prone to static and fatigue behavior. Wear phenomena are also a common problem with splines. To address these issues, it is essential to understand the behavior and predictability of these couplings.

Dynamic behavior of spline-rotor couplings is often unclear, particularly if the system is not integrated with the rotor. For example, when a misalignment is not present, the main response frequency is one X-rotating speed. As the misalignment increases, the system starts to vibrate in complex ways. Furthermore, as the shaft orbits depart from the origin, the magnitudes of all the frequencies increase. Thus, research results are useful in determining proper design and troubleshooting of rotor systems.

The model of misaligned spline couplings can be obtained by analyzing the stress-compression relationships between two spline pairs. The meshing force model of splines is a function of the system mass, transmitting torque, and dynamic vibration displacement. This model holds when the dynamic vibration displacement is small. Besides, the CZPT stepping integration method is stable and has high efficiency.

The slip distributions are a function of the state of lubrication, coefficient of friction, and loading cycles. The predicted wear depths are well within the range of measured values. These predictions are based on the slip distributions. The methodology predicts increased wear under lightly lubricated conditions, but not under added lubrication. The lubrication condition and coefficient of friction are the key factors determining the wear behavior of splines.

editor by czh

China Standard 3490 Splined yoke, PTO Drive Shaft (Triangular tube, Lemon tube) Cross journal Full Series Parts for farm tractor parts with Hot selling

Situation: New

Warranty: 1 Calendar year

Relevant Industries: Resorts, Garment Stores, Building Material Retailers, Production Plant, Machinery Fix Shops, Foods & Beverage Manufacturing facility, Farms, Restaurant, House Use, Retail, Foodstuff Shop, Printing Outlets, Design works , Vitality & Mining, Meals & Beverage Retailers, Other, Marketing Firm

Weight (KG): 1.4 KG

Showroom Location: None

Movie outgoing-inspection: Offered

Equipment Examination Report: Provided

Advertising Sort: Normal Solution

Kind: Spline Yoke

Use: Tractor and Tractor Implements

Product Title: 34*ninety Splined yoke, PTO Travel Shaft

Materials: Forging 1045C

Shade: Yellow

Process: Forging

Certification: CE ISO TS

Teeth: 1 3/8” Z6

Use: PTO Shaft

Cross Package: 34*ninety

Yoke Variety: 01 Push Pin Yoke

MOQ: 1

Packaging Specifics: Plastic bag+ Woodencase + According to Customer’s ask for

Port: ZheJiang or HangZhou

Model Amount 34.0501B Splined YokeFunctionDrive Shaft Components & Energy TransmissionUseKinds of Tractors & Farm ImplementsBrand Name9KYoke TypeDouble drive pin,Bolt pins,Break up pins,Press pin,Fast release,Ball attachment,Collar…..Processing Of YokeForgingPlastic CoverYWBWYS Various varieties GBT 5836.1-2006 pvc reducer pipe fitting bushing BSEtcColorGreenOrangeYellowBlack Ect.SeriesT1-T10 L1-L6S6-S1010HP-150HP with SA,RA,SB,SFF,WA,CV EtcTube TypeLemon,Trianglar,Star,Square,Hexangular,Spline,Special EctProcessing Of TubeCold drawnSpline Type1 1/8″ Z61 3/8″ Z6 1 3/8″ Z21 1 3/4″ Z20 1 3/4″ Z6 wheel plastic wheel slide door roller wheel 8-38*32*6 8-42*36*7 8-forty eight*42*8Place of OriginHangZhou, China (Mainland) ZHangZhoug Jiukai Generate Shaft Co., Ltd. positioned in Changan Industrial Park HangZhou Metropolis, 2 hours to the Xihu (West Lake) Dis. Airport and 1 hour to the Xihu (West Lake) Dis. Airport & the East of HangZhou Station,Covered far more than 12,000 m² with in excess of a hundred folks on staff. We’re specialized in developing,manufacturing and marketing and advertising PTO Shaft, Industrial Cardan Shaft, Vehicle Driveshaft, U-Joint Coupling Shaft and Universal Joint and so forth. The yearly turnover is sixty million RMB, 9 Million Bucks,and It’s increasing 12 months by year. Our merchandise gained excellent reputation from Europe, American, Asia, Australia, and North American consumers. And we are the top3 specialist OEM provider for numerous factory of Agricultural Implements in domestic industry. Jiukai Driveshaft insisted our “QDP” ideas : High quality 1st, Provide rapidly , Price tag Competitive. We presently obtained the CE, TS/16949, ISO9001 Certificates and with systematic manufacturing equipments and QC team to ensure our top quality and supply. We warmly welcome every good friend to go to us and establish the mutual beneficial extended-time period relationship cooperation.

What is a driveshaft and how significantly does it cost to change one?

Your vehicle is made up of numerous transferring components. Being aware of every element is essential due to the fact a broken driveshaft can critically damage other parts of the automobile. You may not know how critical your driveshaft is, but it truly is essential to know if you want to repair your car. In this article, we’ll talk about what a driveshaft is, what its indicators are, and how significantly it expenses to replace a driveshaft.

Restore broken driveshafts

A destroyed driveshaft does not permit you to change the wheels freely. It also exposes your car to increased mend costs because of to damaged driveshafts. If the travel shaft breaks even though the car is in movement, it may cause a crash. Also, it can considerably affect the overall performance of the car. If you do not resolve the dilemma correct absent, you could chance far more costly repairs. If you suspect that the push shaft is broken, do the adhering to.

Very first, make certain the drive shaft is guarded from dust, humidity, and dust. A appropriate driveshaft include will stop grease from accumulating in the driveshaft, reducing the likelihood of even more hurt. The grease will also cushion the metal-to-metallic make contact with in the continuous velocity joints. For illustration, hitting a delicate materials is much better than hitting a steel wall. A destroyed prop shaft can not only result in challenging cornering, but it can also lead to the automobile to vibrate, which can even more damage the relaxation of the drivetrain.

If the driveshaft is damaged, you can choose to fix it oneself or get it to a mechanic. Normally, driveshaft repairs value close to $200 to $300. Elements and labor may vary based on your motor vehicle kind and sort of restore. These components can price up to $600. However, if you will not have a mechanical track record, it truly is greater to go away it to a expert.

If you recognize that one of the two generate shafts is worn, it is time to repair it. Worn bushings and bearings can result in the push shaft to vibrate unnecessarily, creating it to break and trigger additional harm. You can also check the middle bearing if there is any enjoy in the bearing. If these signs arise, it is best to get your automobile to a mechanic as soon as achievable.

Learn about U-joints

Although most autos have at minimum 1 variety of U-joint, there are other kinds accessible. CV joints (also identified as sizzling rod joints) are employed in a range of apps. The minimal axis is shorter than the main axis on which the U-joint is positioned. In each cases, the U-joints are lubricated at the factory. For the duration of servicing, the travel shaft slip joint must be lubricated.

There are two major types of U-joints, such as solid and push suit. They are typically held in area by C-clamps. Some of these U-joints have knurls or grooves. When picking the correct fitting, be certain to measure the total fitting. To make confident you get the correct measurement, you can use the measurement chart or check the manual for your certain design.

In addition to lubrication, the problem of the U-joint should be checked regularly. Lubricate them routinely to keep away from premature failure. If you listen to a clicking seem when shifting gears, the u-joint area may be misaligned. In this case, the bearing may require to be serviced. If there is insufficient grease in the bearings, the universal joint could need to have to be replaced.

U-joint is an important portion of the vehicle transmission shaft. Without having them, your automobile would have no wheeled suspension. With out them, your vehicle will have a rickety front conclude and a wobbly rear finish. Because vehicles are unable to push on ultra-flat surfaces, they require flexible driveshafts. The U-joint compensates for this by allowing it to transfer up and down with the suspension.

A correct inspection will decide if your u-joints are free or worn. It must be simple to pull them out. Make positive not to pull them all the way out. Also, the bearing caps ought to not shift. Any indications of roughness or wear would point out a need for a new UJ. Also, it is critical to observe that worn UJs are not able to be fixed.

Signs and symptoms of Driveshaft Failure

One of the most common issues connected with a faulty driveshaft is difficulty turning the wheels. This severely limitations your general management in excess of the car. Fortunately, there are numerous signs that could point out that your driveshaft is failing. You must get fast methods to figure out the result in of the difficulty. A single of the most common causes of driveshaft failure is a weak or defective reverse equipment. Other common brings about of driveshaft harm incorporate driving too tough, receiving caught in reverse gear and differential lock.

An additional indication of a unsuccessful driveshaft is uncommon sounds while driving. These noises are usually the end result of dress in on the bushings and bearings that assistance the push shaft. They can also lead to your car to screech or scratch when switching from travel to idle. Relying on the velocity, the sounds may be accompanied by vibration. When this occurs, it’s time to send your car in for a driveshaft replacement.

A single of the most frequent signs and symptoms of driveshaft failure is noticeable jitter when accelerating. This could be a indicator of a loose U-joint or worn center bearing. You ought to extensively inspect your auto to decide the trigger of these seems and corresponding indicators. A licensed mechanic can assist you establish the result in of the noise. A broken propshaft can severely restrict the drivability of the automobile.

Regular inspection of the drive shaft can avoid severe harm. Relying on the hurt, you can change the driveshaft for wherever from $500 to $1,000. Depending on the severity of the harm and the level of fix, the cost will depend on the amount of areas that need to have to be replaced. Do not push with a negative driveshaft as it can lead to a critical crash. There are numerous methods to avoid this issue fully.

The very first symptom to appear for is a worn U-joint. If the U-joint comes unfastened or moves way too much when trying to turn the steering wheel, the driveshaft is faulty. If you see obvious rust on the bearing cap seals, you can get your car to a mechanic for a thorough inspection. A worn u-joint can also reveal a issue with the transmission.

The expense of replacing the travel shaft

Relying on your point out and support middle, a driveshaft mend can expense as minor as $three hundred or as higher as $2,000, relying on the particulars of your car. Labor charges are normally around $70. Costs for the parts themselves assortment from $four hundred to $600. Labor fees also fluctuate by design and car make. Ultimately, the choice to restore or exchange the driveshaft will rely on whether you want a rapid car repair or a complete car restore.

Some cars have two individual driveshafts. One particular goes to the entrance and the other goes to the again. If your automobile has 4 wheel travel, you will have two. If you might be changing the axles of an all-wheel-push automobile, you will need a unique part for every axle. Choosing the mistaken one can end result in more expensive repairs. Before you begin shopping, you should know just how significantly it will cost.

Depending on the type of vehicle you very own, a driveshaft replacement will price in between PS250 and PS500. Luxury vehicles can price as significantly as PS400. Nonetheless, for safety and the overall overall performance of the auto, replacing the driveshaft may possibly be a required restore. The price of changing a driveshaft relies upon on how extended your car has been on the street and how much wear and tear it has skilled. There are some signs and symptoms that indicate a faulty generate shaft and you need to get fast action.

Repairs can be expensive, so it really is ideal to employ the service of a mechanic with expertise in the subject. You will be shelling out hundreds of bucks a month, but you are going to have peace of head being aware of the occupation will be completed correct. Keep in mind that you could want to question a friend or family members member to aid you. Dependent on the make and model of your auto, replacing the driveshaft is a lot more expensive than replacing the elements and carrying out it your self.

If you suspect that your drive shaft is destroyed, be positive to resolve it as soon as feasible. It is not recommended to travel a automobile with irregular vibration and sound for a long time. Luckily, there are some quick techniques to resolve the difficulty and keep away from costly repairs later on. If you’ve got seen the signs and symptoms above, it is value receiving the task done. There are a lot of signs that your driveshaft might want service, like absence of power or issues relocating the motor vehicle.