Product Description

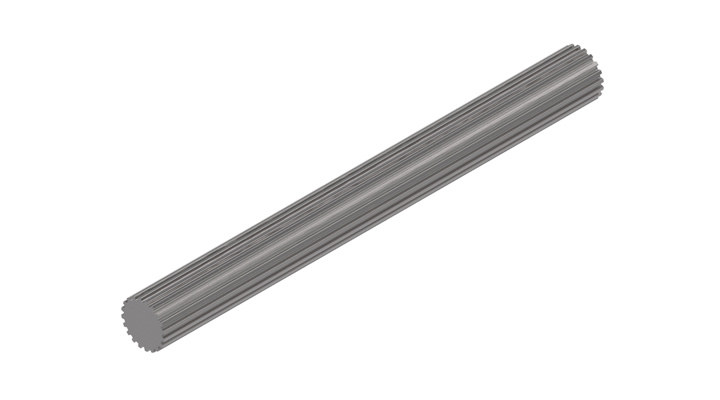

Good Quality spline pto shaft for Farm Tractor Inner Tubes

1. Tubes or Pipes

We’ve already got Triangular profile tube and Lemon profile tube for all the series we provide.

And we have some star tube, splined tube and other profile tubes required by our customers (for a certain series). (Please notice that our catalog doesnt contain all the items we produce)

If you want tubes other than triangular or lemon, please provide drawings or pictures.

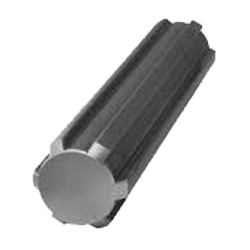

2.End yokes

We’ve got several types of quick release yokes and plain bore yoke. I will suggest the usual type for your reference.

You can also send drawings or pictures to us if you cannot find your item in our catalog.

3. Safety devices or clutches

I will attach the details of safety devices for your reference. We’ve already have Free wheel (RA), Ratchet torque limiter(SA), Shear bolt torque limiter(SB), 3types of friction torque limiter (FF,FFS,FCS) and overrunning couplers(adapters) (FAS).

4.For any other more special requirements with plastic guard, connection method, color of painting, package, etc., please feel free to let me know.

Features:

1. We have been specialized in designing, manufacturing drive shaft, steering coupler shaft, universal joints, which have exported to the USA, Europe, Australia etc for years

2. Application to all kinds of general mechanical situation

3. Our products are of high intensity and rigidity.

4. Heat resistant & Acid resistant

5. OEM orders are welcomed

Our factory is a leading manufacturer of PTO shaft yoke and universal joint.

We manufacture high quality PTO yokes for various vehicles, construction machinery and equipment. All products are constructed with rotating lighter.

We are currently exporting our products throughout the world, especially to North America, South America, Europe, and Russia. If you are interested in any item, please do not hesitate to contact us. We are looking CHINAMFG to becoming your suppliers in the near future.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Fork |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying |

| Material: | Carbon Steel |

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the different types of spline profiles and their applications?

Spline profiles are used in various applications to transmit torque and motion between mating components. Here’s a detailed explanation of different spline profiles and their applications:

1. Involute Splines:

Involute splines have a trapezoidal tooth profile that allows for smooth engagement and disengagement. They are widely used in power transmission applications, such as automotive gearboxes, where high torque transmission is required. Involute splines provide excellent load distribution and can accommodate misalignment.

2. Straight Sided Splines:

Straight sided splines have straight-sided teeth that provide efficient torque transmission and high torsional stiffness. They are commonly used in applications where precise positioning is required, such as machine tools, robotics, and aerospace systems. Straight sided splines offer accurate motion control and are resistant to misalignment.

3. Serrations:

Serrations are a type of spline profile with multiple teeth in the form of parallel ridges and grooves. They are often used in applications that involve axial or linear motion, such as indexing mechanisms, clamping systems, or power tools. Serrations provide secure locking and positioning capabilities.

4. Helical Splines:

Helical splines have teeth that are helically shaped, similar to helical gears. They offer smooth and gradual tooth engagement, resulting in reduced noise and vibration. Helical splines are commonly used in applications that require high torque transmission and where quiet operation is critical, such as heavy machinery, industrial equipment, and automotive drivetrains.

5. Crowned Splines:

Crowned splines have a modified tooth profile with a slight curvature along the tooth length. This design helps distribute the load evenly across the tooth surfaces, reducing stress concentrations and improving load-carrying capacity. Crowned splines are used in applications where high load capacity and resistance to wear are essential, such as heavy-duty gearboxes, marine propulsion systems, or mining equipment.

6. Ball Splines:

Ball splines incorporate recirculating ball bearings within the spline nut and grooves on the shaft. This design enables linear motion with low friction and high precision. Ball splines are commonly used in applications that require smooth linear motion, such as CNC machines, robotics, or linear actuators.

7. Custom Splines:

In addition to the standard spline profiles mentioned above, custom spline profiles can be designed for specific applications based on unique requirements. Custom splines can be tailored to optimize torque transmission, load distribution, misalignment compensation, or other specific performance parameters.

The choice of spline profile depends on factors such as the magnitude of torque, required accuracy, misalignment tolerance, noise and vibration considerations, and environmental conditions. Engineers and designers carefully select the appropriate spline profile to ensure optimal performance and reliability in the intended application.

How do spline shafts handle variations in environmental conditions?

Spline shafts are designed to handle variations in environmental conditions and maintain their performance and reliability. Here’s a detailed explanation:

1. Temperature Variations:

Spline shafts are engineered to withstand a wide range of temperature variations. They are constructed from materials that exhibit good thermal stability, such as high-grade steels or alloys. These materials have low coefficients of thermal expansion, minimizing the effects of temperature changes on the shaft’s dimensional stability. Additionally, proper lubrication with temperature-resistant lubricants helps reduce friction and wear in the spline engagement, even under extreme temperature conditions.

2. Moisture and Corrosion Resistance:

Spline shafts can be designed to resist moisture and corrosion, ensuring their performance in humid or corrosive environments. Protective coatings, such as platings or surface treatments, can be applied to the shaft’s surfaces to enhance their resistance to moisture, oxidation, and corrosion. Additionally, selecting materials with inherent corrosion resistance, such as stainless steel or specialized alloys, can further enhance the spline shaft’s ability to handle environmental conditions.

3. Dust and Contaminant Protection:

Spline shafts used in environments with high levels of dust, dirt, or contaminants can be equipped with protective measures. Seals, gaskets, or covers can be employed to prevent the ingress of particles into the spline engagement. These protective measures help maintain the integrity of the spline profile, minimize wear, and ensure smooth operation even in dirty or dusty conditions.

4. Lubrication and Maintenance:

Proper lubrication is essential for the reliable operation of spline shafts, especially in challenging environmental conditions. Lubricants with appropriate viscosity and additives can be selected to provide effective lubrication and protection against wear, friction, and corrosion. Regular maintenance and lubrication intervals should be followed to ensure optimal performance and longevity of the spline shaft.

5. Shock and Vibration Resistance:

Spline shafts are designed to withstand shock and vibration encountered in various applications. The spline engagement and shaft design can incorporate features such as tighter tolerances, increased contact area, or damping elements to minimize the effects of shock and vibration. Additionally, proper fastening and mounting techniques help secure the shaft and reduce the risk of loosening or failure due to dynamic loads.

6. Environmental Sealing:

In certain applications where spline shafts are exposed to harsh environmental conditions, such as underwater or in chemical environments, environmental sealing can be employed. Sealing methods such as O-rings, gaskets, or specialized seals provide an additional barrier against external elements, ensuring the integrity and performance of the spline shaft.

7. Compliance with Standards:

Spline shafts used in specific industries or applications may need to comply with industry standards or regulations regarding environmental conditions. Manufacturers can design and test their spline shafts to meet these requirements, ensuring that the shafts can handle the specified environmental conditions and perform reliably.

By incorporating design considerations, appropriate materials, protective coatings, lubrication, and maintenance practices, spline shafts can effectively handle variations in environmental conditions. This enables them to maintain their functionality, performance, and longevity even in challenging operating environments.

Can you explain the common applications of spline shafts in machinery?

Spline shafts have various common applications in machinery where torque transmission, relative movement, and load distribution are essential. Here’s a detailed explanation:

1. Gearboxes and Transmissions:

Spline shafts are commonly used in gearboxes and transmissions where they facilitate the transmission of torque from the input shaft to the output shaft. The splines on the shaft engage with corresponding splines on the gears, allowing for precise torque transfer and accommodating relative movement between the gears.

2. Power Take-Off (PTO) Units:

In agricultural and industrial machinery, spline shafts are employed in power take-off (PTO) units. PTO units allow the transfer of power from the engine to auxiliary equipment, such as pumps, generators, or farm implements. Spline shafts enable the torque transfer and accommodate the relative movement required for PTO operation.

3. Steering Systems:

Spline shafts play a crucial role in steering systems, especially in vehicles. They are used in steering columns to transmit torque from the steering wheel to the steering rack or gearbox. The splines on the shaft ensure precise torque transfer while allowing for the axial movement required for steering wheel adjustment.

4. Machine Tools:

Spline shafts find applications in machine tools such as milling machines, lathes, and grinding machines. They are used to transmit torque and enable the relative movement required for tool positioning, feed control, and spindle rotation. Spline shafts ensure accurate and controlled movement of the machine tool components.

5. Industrial Pumps and Compressors:

Spline shafts are utilized in various types of pumps and compressors, including centrifugal pumps, gear pumps, and reciprocating compressors. They transmit torque from the driver (such as an electric motor or an engine) to the impeller or rotor, enabling fluid or gas transfer. Spline shafts accommodate the axial or radial movement caused by thermal expansion or misalignment.

6. Printing and Packaging Machinery:

Spline shafts are integral components in printing and packaging machinery. They are used in processes such as web handling, where precise torque transmission and relative movement are required for tasks like tension control, registration, and material feeding. Spline shafts ensure accurate and synchronized movement of the printing and packaging elements.

7. Aerospace and Defense Systems:

In the aerospace and defense industries, spline shafts are utilized in various applications, including aircraft landing gear systems, missile guidance systems, and helicopter rotor systems. They enable torque transmission, accommodate relative movement, and ensure precise control in critical aerospace and defense mechanisms.

8. Construction and Earthmoving Equipment:

Spline shafts are employed in construction and earthmoving equipment, such as excavators, bulldozers, and loaders. They are used in hydraulic systems to transmit torque from the hydraulic motor to the driven components, such as the digger arm or the bucket. Spline shafts enable efficient power transfer and allow for the articulation and movement of the equipment.

These are just a few examples of the common applications of spline shafts in machinery. Their versatility, torque transmission capabilities, and ability to accommodate relative movement make them essential components in various industries where precise power transfer and flexibility are required.

editor by CX 2024-03-27

China manufacturer Good Quality Spline Pto Shaft for Farm Tractor Inner Tubes

Product Description

Good Quality spline pto shaft for Farm Tractor Inner Tubes

1. Tubes or Pipes

We’ve already got Triangular profile tube and Lemon profile tube for all the series we provide.

And we have some star tube, splined tube and other profile tubes required by our customers (for a certain series). (Please notice that our catalog doesnt contain all the items we produce)

If you want tubes other than triangular or lemon, please provide drawings or pictures.

2.End yokes

We’ve got several types of quick release yokes and plain bore yoke. I will suggest the usual type for your reference.

You can also send drawings or pictures to us if you cannot find your item in our catalog.

3. Safety devices or clutches

I will attach the details of safety devices for your reference. We’ve already have Free wheel (RA), Ratchet torque limiter(SA), Shear bolt torque limiter(SB), 3types of friction torque limiter (FF,FFS,FCS) and overrunning couplers(adapters) (FAS).

4.For any other more special requirements with plastic guard, connection method, color of painting, package, etc., please feel free to let me know.

Features:

1. We have been specialized in designing, manufacturing drive shaft, steering coupler shaft, universal joints, which have exported to the USA, Europe, Australia etc for years

2. Application to all kinds of general mechanical situation

3. Our products are of high intensity and rigidity.

4. Heat resistant & Acid resistant

5. OEM orders are welcomed

Our factory is a leading manufacturer of PTO shaft yoke and universal joint.

We manufacture high quality PTO yokes for various vehicles, construction machinery and equipment. All products are constructed with rotating lighter.

We are currently exporting our products throughout the world, especially to North America, South America, Europe, and Russia. If you are interested in any item, please do not hesitate to contact us. We are looking CHINAMFG to becoming your suppliers in the near future.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Type: | Fork |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying |

| Material: | Carbon Steel |

| Customization: |

Available

| Customized Request |

|---|

Can spline shafts be customized for specific machinery and equipment?

Yes, spline shafts can be customized to suit specific machinery and equipment requirements. Here’s a detailed explanation:

1. Size and Length:

Spline shafts can be customized in terms of size and length to fit the dimensions of the machinery or equipment. Manufacturers can design spline shafts with the appropriate diameter, overall length, and spline length to ensure a proper fit within the system.

2. Spline Profile:

The spline profile can be customized based on the specific application. Different spline profiles, such as involute, serrated, or helical, can be used to optimize torque transmission, load distribution, and engagement characteristics based on the requirements of the machinery or equipment.

3. Number of Splines:

The number of splines on the shaft can be customized to match the mating component. The number of splines determines the engagement area and affects the torque-carrying capacity of the spline shaft. By adjusting the number of splines, manufacturers can tailor the spline shaft to the specific torque and load requirements of the machinery or equipment.

4. Material Selection:

The choice of material for spline shafts can be customized based on the operating conditions and environmental factors of the machinery or equipment. Different materials, such as alloy steels or stainless steels, can be selected to provide the necessary strength, durability, corrosion resistance, or other specific properties required for the application.

5. Surface Treatment:

The surface of spline shafts can be customized with various treatments to enhance their performance. Surface treatments like heat treatment, coating, or plating can be applied to improve hardness, wear resistance, or corrosion resistance based on the specific requirements of the machinery or equipment.

6. Tolerances and Fit:

Tolerances and fit between the spline shaft and mating components can be customized to achieve the desired clearance or interference fit. This ensures proper engagement, smooth operation, and optimal performance of the machinery or equipment.

7. Special Features:

In certain cases, spline shafts can be customized with additional features to meet specific needs. This may include the incorporation of keyways, threads, or other specialized features required for the machinery or equipment.

Manufacturers and engineers work closely with the machinery or equipment designers to understand the specific requirements and tailor the spline shafts accordingly. By considering factors such as size, spline profile, number of splines, material selection, surface treatment, tolerances, fit, and any special features, customized spline shafts can be developed to ensure optimal performance and compatibility with the machinery or equipment.

It is important to consult with experienced spline shaft manufacturers or engineering professionals to determine the most suitable customization options for a particular machinery or equipment application.

How do spline shafts contribute to precise and consistent rotation?

Spline shafts play a crucial role in achieving precise and consistent rotation in mechanical systems. Here’s how spline shafts contribute to these characteristics:

1. Interlocking Design:

Spline shafts feature a series of ridges or teeth, known as splines, that interlock with corresponding grooves or slots in mating components. This interlocking design ensures a positive connection between the shaft and the mating part, allowing for precise and consistent rotation. The engagement between the splines provides resistance to axial and radial movement, minimizing play or backlash that can introduce inaccuracies in rotation.

2. Load Distribution:

The interlocking engagement of spline shafts allows for effective load distribution along the length of the shaft. This helps distribute the applied torque evenly, reducing stress concentrations and minimizing the risk of localized deformation or failure. By distributing the load, spline shafts contribute to consistent rotation and prevent excessive wear on specific areas of the shaft or the mating components.

3. Torque Transmission:

Spline shafts are specifically designed to transmit torque efficiently from one component to another. The close fit between the splines ensures a high torque-carrying capacity, enabling the shaft to transfer rotational force without significant power loss. This efficient torque transmission contributes to precise and consistent rotation, allowing for accurate positioning and motion control in various applications.

4. Rigidity and Stiffness:

Spline shafts are typically constructed from materials with high rigidity and stiffness, such as steel or alloy. This inherent rigidity helps maintain the dimensional integrity of the shaft and minimizes deflection or bending under load. By providing a stable and stiff rotational axis, spline shafts contribute to precise and consistent rotation, particularly in applications that require tight tolerances or high-speed operation.

5. Alignment and Centering:

The interlocking nature of spline shafts aids in the alignment and centering of rotating components. The splines ensure proper positioning and orientation of the shaft relative to the mating part, facilitating concentric rotation. This alignment helps prevent wobbling, vibrations, and eccentricity, which can adversely affect rotation accuracy and consistency.

6. Lubrication and Wear Reduction:

Proper lubrication of spline shafts is essential for maintaining precise and consistent rotation. Lubricants reduce friction between the mating surfaces, minimizing wear and preventing stick-slip phenomena that can cause irregular rotation. The use of lubrication also helps dissipate heat generated during operation, ensuring optimal performance and longevity of the spline shaft.

By incorporating interlocking design, load distribution, efficient torque transmission, rigidity, alignment, and lubrication, spline shafts contribute to precise and consistent rotation in mechanical systems. Their reliable and accurate rotational characteristics make them suitable for a wide range of applications, from automotive and aerospace to machinery and robotics.

What are the key components and design features of a spline shaft?

A spline shaft consists of several key components and incorporates specific design features to ensure its functionality and performance. Here’s a detailed explanation:

1. Shaft Body:

The main component of a spline shaft is the shaft body, which provides the structural integrity and serves as the base for the spline features. The shaft body is typically cylindrical in shape and made from materials such as steel, stainless steel, or other alloyed metals. The material selection depends on factors like the application requirements, torque loads, and environmental conditions.

2. Splines:

The splines are the key design feature of a spline shaft. They are ridges or teeth that are machined onto the surface of the shaft. The splines create the interlocking mechanism with mating components, allowing for torque transmission and relative movement. The number, size, and shape of the splines can vary depending on the application requirements and design specifications.

3. Spline Profile:

The spline profile refers to the specific shape or geometry of the splines. Common types of spline profiles include involute, straight-sided, and serrated. The spline profile is chosen based on factors such as the torque transmission requirements, load distribution, and the desired engagement characteristics with mating components. The spline profile ensures optimal contact and torque transfer between the spline shaft and the mating component.

4. Spline Fit:

The spline fit refers to the dimensional relationship between the spline shaft and the mating component. It determines the clearance or interference between the splines, ensuring proper engagement and transmission of torque. The spline fit can be categorized into different classes, such as clearance fit, transition fit, or interference fit, based on the desired level of clearance or interference.

5. Surface Finish:

The surface finish of the spline shaft is crucial for its performance. The splines and the shaft body should have a smooth and consistent surface finish to minimize friction, wear, and the risk of stress concentrations. The surface finish can be achieved through machining, grinding, or other surface treatment methods to meet the required specifications.

6. Lubrication:

To ensure smooth operation and reduce wear, lubrication is often employed for spline shafts. Lubricants with appropriate viscosity and lubricating properties are applied to the spline interface to minimize friction, dissipate heat, and prevent premature wear or damage to the splines and mating components. Lubrication also helps in maintaining the functionality and prolonging the service life of the spline shaft.

7. Machining Tolerances:

Precision machining is critical for spline shafts to achieve the required dimensional accuracy and ensure proper engagement with mating components. Tight machining tolerances are maintained during the manufacturing process to ensure the spline profile, dimensions, and surface finish meet the specified design requirements. This ensures the interchangeability and compatibility of spline shafts in various applications.

In summary, the key components and design features of a spline shaft include the shaft body, splines, spline profile, spline fit, surface finish, lubrication, and machining tolerances. These elements work together to enable torque transmission, relative movement, and load distribution while ensuring the functionality, durability, and performance of the spline shaft.

editor by CX 2023-09-23

China factory Good Quality Spline Pto Shaft for Farm Tractor Inner Tubes drive shaft carrier bearing

Product Description

Good Quality spline pto shaft for Farm Tractor Inner Tubes

1. Tubes or Pipes

We’ve already got Triangular profile tube and Lemon profile tube for all the series we provide.

And we have some star tube, splined tube and other profile tubes required by our customers (for a certain series). (Please notice that our catalog doesnt contain all the items we produce)

If you want tubes other than triangular or lemon, please provide drawings or pictures.

2.End yokes

We’ve got several types of quick release yokes and plain bore yoke. I will suggest the usual type for your reference.

You can also send drawings or pictures to us if you cannot find your item in our catalog.

3. Safety devices or clutches

I will attach the details of safety devices for your reference. We’ve already have Free wheel (RA), Ratchet torque limiter(SA), Shear bolt torque limiter(SB), 3types of friction torque limiter (FF,FFS,FCS) and overrunning couplers(adapters) (FAS).

4.For any other more special requirements with plastic guard, connection method, color of painting, package, etc., please feel free to let me know.

Features:

1. We have been specialized in designing, manufacturing drive shaft, steering coupler shaft, universal joints, which have exported to the USA, Europe, Australia etc for years

2. Application to all kinds of general mechanical situation

3. Our products are of high intensity and rigidity.

4. Heat resistant & Acid resistant

5. OEM orders are welcomed

Our factory is a leading manufacturer of PTO shaft yoke and universal joint.

We manufacture high quality PTO yokes for various vehicles, construction machinery and equipment. All products are constructed with rotating lighter.

We are currently exporting our products throughout the world, especially to North America, South America, Europe, and Russia. If you are interested in any item, please do not hesitate to contact us. We are looking CZPT to becoming your suppliers in the near future.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated|

|

|---|

| Type: | Fork |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying |

| Material: | Carbon Steel |

| Customization: |

Available

| Customized Request |

|---|

The Benefits of Spline Couplings for Disc Brake Mounting Interfaces

Spline couplings are commonly used for securing disc brake mounting interfaces. Spline couplings are often used in high-performance vehicles, aeronautics, and many other applications. However, the mechanical benefits of splines are not immediately obvious. Listed below are the benefits of spline couplings. We’ll discuss what these advantages mean for you. Read on to discover how these couplings work.

Disc brake mounting interfaces are splined

There are two common disc brake mounting interfaces – splined and six-bolt. Splined rotors fit on splined hubs; six-bolt rotors will need an adapter to fit on six-bolt hubs. The six-bolt method is easier to maintain and may be preferred by many cyclists. If you’re thinking of installing a disc brake system, it is important to know how to choose the right splined and center lock interfaces.

Aerospace applications

The splines used for spline coupling in aircraft are highly complex. While some previous researches have addressed the design of splines, few publications have tackled the problem of misaligned spline coupling. Nevertheless, the accurate results we obtained were obtained using dedicated simulation tools, which are not commercially available. Nevertheless, such tools can provide a useful reference for our approach. It would be beneficial if designers could use simple tools for evaluating contact pressure peaks. Our analytical approach makes it possible to find answers to such questions.

The design of a spline coupling for aerospace applications must be accurate to minimize weight and prevent failure mechanisms. In addition to weight reduction, it is necessary to minimize fretting fatigue. The pressure distribution on the spline coupling teeth is a significant factor in determining its fretting fatigue. Therefore, we use analytical and experimental methods to examine the contact pressure distribution in the axial direction of spline couplings.

The teeth of a spline coupling can be categorized by the type of engagement they provide. This study investigates the position of resultant contact forces in the teeth of a spline coupling when applied to pitch diameter. Using FEM models, numerical results are generated for nominal and parallel offset misalignments. The axial tooth profile determines the behavior of the coupling component and its ability to resist wear. Angular misalignment is also a concern, causing misalignment.

In order to assess wear damage of a spline coupling, we must take into consideration the impact of fretting on the components. This wear is caused by relative motion between the teeth that engage them. The misalignment may be caused by vibrations, cyclical tooth deflection, or angular misalignment. The result of this analysis may help designers improve their spline coupling designs and develop improved performance.

CZPT polyimide, an abrasion-resistant polymer, is a popular choice for high-temperature spline couplings. This material reduces friction and wear, provides a low friction surface, and has a low wear rate. Furthermore, it offers up to 50 times the life of metal on metal spline connections. For these reasons, it is important to choose the right material for your spline coupling.

High-performance vehicles

A spline coupler is a device used to connect splined shafts. A typical spline coupler resembles a short pipe with splines on either end. There are two basic types of spline coupling: single and dual spline. One type attaches to a drive shaft, while the other attaches to the gearbox. While spline couplings are typically used in racing, they’re also used for performance problems.

The key challenge in spline couplings is to determine the optimal dimension of spline joints. This is difficult because no commercial codes allow the simulation of misaligned joints, which can destroy components. This article presents analytical approaches to estimating contact pressures in spline connections. The results are comparable with numerical approaches but require special codes to accurately model the coupling operation. This research highlights several important issues and aims to make the application of spline couplings in high-performance vehicles easier.

The stiffness of spline assemblies can be calculated using tooth-like structures. Such splines can be incorporated into the spline joint to produce global stiffness for torsional vibration analysis. Bearing reactions are calculated for a certain level of misalignment. This information can be used to design bearing dimensions and correct misalignment. There are three types of spline couplings.

Major diameter fit splines are made with tightly controlled outside diameters. This close fit provides concentricity transfer from the male to the female spline. The teeth of the male spline usually have chamfered tips and clearance with fillet radii. These splines are often manufactured from billet steel or aluminum. These materials are renowned for their strength and uniform grain created by the forging process. ANSI and DIN design manuals define classes of fit.

Disc brake mounting interfaces

A spline coupling for disc brake mounting interfaces is a type of hub-to-brake-disc mount. It is a highly durable coupling mechanism that reduces heat transfer from the disc to the axle hub. The mounting arrangement also isolates the axle hub from direct contact with the disc. It is also designed to minimize the amount of vehicle downtime and maintenance required to maintain proper alignment.

Disc brakes typically have substantial metal-to-metal contact with axle hub splines. The discs are held in place on the hub by intermediate inserts. This metal-to-metal contact also aids in the transfer of brake heat from the brake disc to the axle hub. Spline coupling for disc brake mounting interfaces comprises a mounting ring that is either a threaded or non-threaded spline.

During drag brake experiments, perforated friction blocks filled with various additive materials are introduced. The materials included include Cu-based powder metallurgy material, a composite material, and a Mn-Cu damping alloy. The filling material affects the braking interface’s wear behavior and friction-induced vibration characteristics. Different filling materials produce different types of wear debris and have different wear evolutions. They also differ in their surface morphology.

Disc brake couplings are usually made of two different types. The plain and HD versions are interchangeable. The plain version is the simplest to install, while the HD version has multiple components. The two-piece couplings are often installed at the same time, but with different mounting interfaces. You should make sure to purchase the appropriate coupling for your vehicle. These interfaces are a vital component of your vehicle and must be installed correctly for proper operation.

Disc brakes use disc-to-hub elements that help locate the forces and displace them to the rim. These elements are typically made of stainless steel, which increases the cost of manufacturing the disc brake mounting interface. Despite their benefits, however, the high braking force loads they endure are hard on the materials. Moreover, excessive heat transferred to the intermediate elements can adversely affect the fatigue life and long-term strength of the brake system.

editor by CX 2023-04-24

China Standard 3490 Splined yoke, PTO Drive Shaft (Triangular tube, Lemon tube) Cross journal Full Series Parts for farm tractor parts with Hot selling

Situation: New

Warranty: 1 Calendar year

Relevant Industries: Resorts, Garment Stores, Building Material Retailers, Production Plant, Machinery Fix Shops, Foods & Beverage Manufacturing facility, Farms, Restaurant, House Use, Retail, Foodstuff Shop, Printing Outlets, Design works , Vitality & Mining, Meals & Beverage Retailers, Other, Marketing Firm

Weight (KG): 1.4 KG

Showroom Location: None

Movie outgoing-inspection: Offered

Equipment Examination Report: Provided

Advertising Sort: Normal Solution

Kind: Spline Yoke

Use: Tractor and Tractor Implements

Product Title: 34*ninety Splined yoke, PTO Travel Shaft

Materials: Forging 1045C

Shade: Yellow

Process: Forging

Certification: CE ISO TS

Teeth: 1 3/8” Z6

Use: PTO Shaft

Cross Package: 34*ninety

Yoke Variety: 01 Push Pin Yoke

MOQ: 1

Packaging Specifics: Plastic bag+ Woodencase + According to Customer’s ask for

Port: ZheJiang or HangZhou

Model Amount 34.0501B Splined YokeFunctionDrive Shaft Components & Energy TransmissionUseKinds of Tractors & Farm ImplementsBrand Name9KYoke TypeDouble drive pin,Bolt pins,Break up pins,Press pin,Fast release,Ball attachment,Collar…..Processing Of YokeForgingPlastic CoverYWBWYS Various varieties GBT 5836.1-2006 pvc reducer pipe fitting bushing BSEtcColorGreenOrangeYellowBlack Ect.SeriesT1-T10 L1-L6S6-S1010HP-150HP with SA,RA,SB,SFF,WA,CV EtcTube TypeLemon,Trianglar,Star,Square,Hexangular,Spline,Special EctProcessing Of TubeCold drawnSpline Type1 1/8″ Z61 3/8″ Z6 1 3/8″ Z21 1 3/4″ Z20 1 3/4″ Z6 wheel plastic wheel slide door roller wheel 8-38*32*6 8-42*36*7 8-forty eight*42*8Place of OriginHangZhou, China (Mainland) ZHangZhoug Jiukai Generate Shaft Co., Ltd. positioned in Changan Industrial Park HangZhou Metropolis, 2 hours to the Xihu (West Lake) Dis. Airport and 1 hour to the Xihu (West Lake) Dis. Airport & the East of HangZhou Station,Covered far more than 12,000 m² with in excess of a hundred folks on staff. We’re specialized in developing,manufacturing and marketing and advertising PTO Shaft, Industrial Cardan Shaft, Vehicle Driveshaft, U-Joint Coupling Shaft and Universal Joint and so forth. The yearly turnover is sixty million RMB, 9 Million Bucks,and It’s increasing 12 months by year. Our merchandise gained excellent reputation from Europe, American, Asia, Australia, and North American consumers. And we are the top3 specialist OEM provider for numerous factory of Agricultural Implements in domestic industry. Jiukai Driveshaft insisted our “QDP” ideas : High quality 1st, Provide rapidly , Price tag Competitive. We presently obtained the CE, TS/16949, ISO9001 Certificates and with systematic manufacturing equipments and QC team to ensure our top quality and supply. We warmly welcome every good friend to go to us and establish the mutual beneficial extended-time period relationship cooperation.

What is a driveshaft and how significantly does it cost to change one?

Your vehicle is made up of numerous transferring components. Being aware of every element is essential due to the fact a broken driveshaft can critically damage other parts of the automobile. You may not know how critical your driveshaft is, but it truly is essential to know if you want to repair your car. In this article, we’ll talk about what a driveshaft is, what its indicators are, and how significantly it expenses to replace a driveshaft.

Restore broken driveshafts

A destroyed driveshaft does not permit you to change the wheels freely. It also exposes your car to increased mend costs because of to damaged driveshafts. If the travel shaft breaks even though the car is in movement, it may cause a crash. Also, it can considerably affect the overall performance of the car. If you do not resolve the dilemma correct absent, you could chance far more costly repairs. If you suspect that the push shaft is broken, do the adhering to.

Very first, make certain the drive shaft is guarded from dust, humidity, and dust. A appropriate driveshaft include will stop grease from accumulating in the driveshaft, reducing the likelihood of even more hurt. The grease will also cushion the metal-to-metallic make contact with in the continuous velocity joints. For illustration, hitting a delicate materials is much better than hitting a steel wall. A destroyed prop shaft can not only result in challenging cornering, but it can also lead to the automobile to vibrate, which can even more damage the relaxation of the drivetrain.

If the driveshaft is damaged, you can choose to fix it oneself or get it to a mechanic. Normally, driveshaft repairs value close to $200 to $300. Elements and labor may vary based on your motor vehicle kind and sort of restore. These components can price up to $600. However, if you will not have a mechanical track record, it truly is greater to go away it to a expert.

If you recognize that one of the two generate shafts is worn, it is time to repair it. Worn bushings and bearings can result in the push shaft to vibrate unnecessarily, creating it to break and trigger additional harm. You can also check the middle bearing if there is any enjoy in the bearing. If these signs arise, it is best to get your automobile to a mechanic as soon as achievable.

Learn about U-joints

Although most autos have at minimum 1 variety of U-joint, there are other kinds accessible. CV joints (also identified as sizzling rod joints) are employed in a range of apps. The minimal axis is shorter than the main axis on which the U-joint is positioned. In each cases, the U-joints are lubricated at the factory. For the duration of servicing, the travel shaft slip joint must be lubricated.

There are two major types of U-joints, such as solid and push suit. They are typically held in area by C-clamps. Some of these U-joints have knurls or grooves. When picking the correct fitting, be certain to measure the total fitting. To make confident you get the correct measurement, you can use the measurement chart or check the manual for your certain design.

In addition to lubrication, the problem of the U-joint should be checked regularly. Lubricate them routinely to keep away from premature failure. If you listen to a clicking seem when shifting gears, the u-joint area may be misaligned. In this case, the bearing may require to be serviced. If there is insufficient grease in the bearings, the universal joint could need to have to be replaced.

U-joint is an important portion of the vehicle transmission shaft. Without having them, your automobile would have no wheeled suspension. With out them, your vehicle will have a rickety front conclude and a wobbly rear finish. Because vehicles are unable to push on ultra-flat surfaces, they require flexible driveshafts. The U-joint compensates for this by allowing it to transfer up and down with the suspension.

A correct inspection will decide if your u-joints are free or worn. It must be simple to pull them out. Make positive not to pull them all the way out. Also, the bearing caps ought to not shift. Any indications of roughness or wear would point out a need for a new UJ. Also, it is critical to observe that worn UJs are not able to be fixed.

Signs and symptoms of Driveshaft Failure

One of the most common issues connected with a faulty driveshaft is difficulty turning the wheels. This severely limitations your general management in excess of the car. Fortunately, there are numerous signs that could point out that your driveshaft is failing. You must get fast methods to figure out the result in of the difficulty. A single of the most common causes of driveshaft failure is a weak or defective reverse equipment. Other common brings about of driveshaft harm incorporate driving too tough, receiving caught in reverse gear and differential lock.

An additional indication of a unsuccessful driveshaft is uncommon sounds while driving. These noises are usually the end result of dress in on the bushings and bearings that assistance the push shaft. They can also lead to your car to screech or scratch when switching from travel to idle. Relying on the velocity, the sounds may be accompanied by vibration. When this occurs, it’s time to send your car in for a driveshaft replacement.

A single of the most frequent signs and symptoms of driveshaft failure is noticeable jitter when accelerating. This could be a indicator of a loose U-joint or worn center bearing. You ought to extensively inspect your auto to decide the trigger of these seems and corresponding indicators. A licensed mechanic can assist you establish the result in of the noise. A broken propshaft can severely restrict the drivability of the automobile.

Regular inspection of the drive shaft can avoid severe harm. Relying on the hurt, you can change the driveshaft for wherever from $500 to $1,000. Depending on the severity of the harm and the level of fix, the cost will depend on the amount of areas that need to have to be replaced. Do not push with a negative driveshaft as it can lead to a critical crash. There are numerous methods to avoid this issue fully.

The very first symptom to appear for is a worn U-joint. If the U-joint comes unfastened or moves way too much when trying to turn the steering wheel, the driveshaft is faulty. If you see obvious rust on the bearing cap seals, you can get your car to a mechanic for a thorough inspection. A worn u-joint can also reveal a issue with the transmission.

The expense of replacing the travel shaft

Relying on your point out and support middle, a driveshaft mend can expense as minor as $three hundred or as higher as $2,000, relying on the particulars of your car. Labor charges are normally around $70. Costs for the parts themselves assortment from $four hundred to $600. Labor fees also fluctuate by design and car make. Ultimately, the choice to restore or exchange the driveshaft will rely on whether you want a rapid car repair or a complete car restore.

Some cars have two individual driveshafts. One particular goes to the entrance and the other goes to the again. If your automobile has 4 wheel travel, you will have two. If you might be changing the axles of an all-wheel-push automobile, you will need a unique part for every axle. Choosing the mistaken one can end result in more expensive repairs. Before you begin shopping, you should know just how significantly it will cost.

Depending on the type of vehicle you very own, a driveshaft replacement will price in between PS250 and PS500. Luxury vehicles can price as significantly as PS400. Nonetheless, for safety and the overall overall performance of the auto, replacing the driveshaft may possibly be a required restore. The price of changing a driveshaft relies upon on how extended your car has been on the street and how much wear and tear it has skilled. There are some signs and symptoms that indicate a faulty generate shaft and you need to get fast action.

Repairs can be expensive, so it really is ideal to employ the service of a mechanic with expertise in the subject. You will be shelling out hundreds of bucks a month, but you are going to have peace of head being aware of the occupation will be completed correct. Keep in mind that you could want to question a friend or family members member to aid you. Dependent on the make and model of your auto, replacing the driveshaft is a lot more expensive than replacing the elements and carrying out it your self.

If you suspect that your drive shaft is destroyed, be positive to resolve it as soon as feasible. It is not recommended to travel a automobile with irregular vibration and sound for a long time. Luckily, there are some quick techniques to resolve the difficulty and keep away from costly repairs later on. If you’ve got seen the signs and symptoms above, it is value receiving the task done. There are a lot of signs that your driveshaft might want service, like absence of power or issues relocating the motor vehicle.